Precision in Every Measurement: The World of Calibration Measuring Tools

Explore the essential role of calibration measuring tools, where accuracy meets reliability in a vast array of applications. These items are crucial for ensuring that measurements meet established standards, providing the foundation for quality control in industries ranging from manufacturing to healthcare. Whether you are a technician, engineer, or quality assurance professional, understanding theres products are vital for maintaining the integrity of measurements and outcomes in your work.

The Evolution of Calibration Measuring Tools: From Basic Instruments to Advanced Technology

These items have a rich and diverse history, tracing back to the early days of measurement when humanity first sought to quantify and standardize the natural world. Initially, these items were rudimentary, often constructed from basic materials and designed for simple tasks, such as length or weight. Early civilizations, such as the Egyptians and Mesopotamians, utilized primitive devices like the cubit rod and balance scales, laying the groundwork for precision measurement.

As scientific understanding advanced, particularly during the Renaissance, the development of more sophisticated measuring tools began to emerge. The invention of the micrometer in the 17th century marked a significant leap forward, allowing for incredibly precise measurements in engineering and machining. This innovation paved the way for further advancements, leading to the emergence of these options designed to ensure the accuracy of various devices.

Today, these items have evolved into highly advanced instruments, often incorporating digital technology and sophisticated algorithms. From electronic calipers to laser devices, these items are designed to provide instant, accurate readings, facilitating faster and more reliable processes. This evolution reflects the growing demand for precision in a world that increasingly relies on exact measurements for quality assurance and compliance.

The Cultural Significance of Calibration Measuring Tools

Measuring tools hold significant cultural importance, representing a commitment to accuracy and excellence across various fields. In engineering and manufacturing, these products symbolize the dedication to quality control, ensuring that products meet stringent standards and customer expectations. The use of these items has become a hallmark of professionalism, reflecting a culture that values precision and reliability in its outputs.

In many industries, proper calibration is not merely a best practice but a regulatory requirement. In sectors like pharmaceuticals and food production, these items are vital in adhering to safety and quality standards, thus safeguarding public health. This cultural focus on measurement accuracy underscores the importance in fostering trust between consumers and producers, reinforcing the notion that quality is non-negotiable.

The Design and Features of Calibration Measuring Tools

Measuring tools are known for their intricate design and essential features. Common characteristics include precision measurement capabilities, ease of use, and durability, which are crucial for ensuring accurate in various settings. These items often come equipped with user-friendly interfaces, allowing for straightforward operation, even for those new to processes.

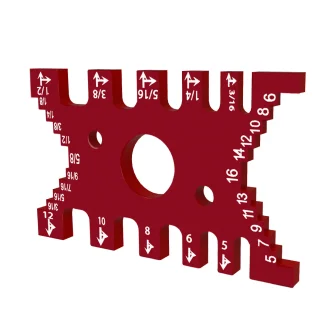

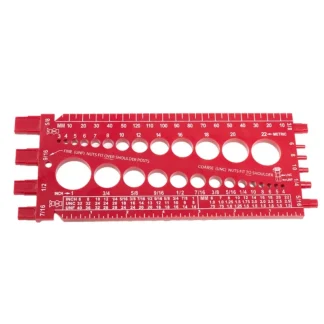

A variety of these items are available, each designed for specific applications. For instance, digital calipers offer precise measurements for internal and external dimensions, while torque wrenches ensure the correct tightening of fasteners. Each item is tailored to meet the unique demands of its intended use, enhancing both functionality and reliability in measurement.

Advanced features, such as data logging capabilities and wireless connectivity, are becoming increasingly common in calibration measuring tools. These innovations allow for seamless integration with software systems, facilitating efficient tracking and management of calibration records. As technology continues to evolve, the emphasis on enhanced functionality and ease of use remains a key focus in the design of these items.

Innovations in Calibration Measuring Tool Design

Recent innovations in these items design have revolutionized the way measurements are taken and calibrated. The integration of smart technology, such as Bluetooth connectivity and mobile applications, has enabled users to collect and analyze data more efficiently. This development has enhanced the accuracy of processes, allowing for real-time monitoring and adjustments.

Customization options are also becoming more prevalent, enabling users to tailor tools to their specific needs. This trend reflects a growing demand for versatile instruments that can adapt to various calibration tasks across different industries. These items become more specialized, the potential for innovative designs that cater to unique applications is expanding.

Sustainability is another important consideration in the development of these items. Many manufacturers are exploring eco-friendly designs and production methods, aiming to minimize environmental impact while maintaining high standards of accuracy and reliability. This shift towards sustainable practices reflects broader trends in responsible manufacturing, promoting a culture of quality that is conscientious about its environmental footprint.

The Future of Calibration Measuring Tools

The future of calibration measuring tools is poised for continued advancement, driven by ongoing innovations in technology and design. As industries increasingly adopt automation and data-driven processes, the demand for these products will only grow. New technologies will likely emerge, further enhancing the capabilities of these instruments and streamlining workflows.

Personalization will remain a significant trend, with advancements in design allowing for tailored solutions that cater to individual preferences and operational requirements. This focus on customization ensures that these products will continue to evolve, reflecting the unique needs of various users and industries.

As technology progresses, calibration measuring tools will incorporate new features that enhance both their functionality and user experience. The emphasis on precision, reliability, and efficiency will ensure that these items remain indispensable in maintaining the highest standards of quality across industries.

Choosing the Right Calibration Measuring Tool

Selecting these products involves considering factors such as the specific application, required precision, and ease of use. For specialized tasks, opt for these items designed specifically for those measurements to ensure accuracy and reliability. If versatility is essential, look for these items that offer multiple measurement capabilities to accommodate a range of applications.

It’s also important to consider the design and features of the item to ensure it aligns with your operational needs. Tools with user-friendly interfaces and advanced features can significantly enhance the efficiency of processes, making it easier to maintain consistent quality across measurements.

Confidence in your choice will not only streamline your calibration efforts but also enhance the overall quality of your work. Embrace the precision and reliability of these items, and discover how they can elevate your measurement practices, contributing to a culture of excellence and accountability in your field.

Conclusion: The Enduring Importance of Calibration Measuring Tools

Measuring tools embody the perfect blend of precision and reliability, offering essential solutions for maintaining measurement integrity across various industries. Their evolution from basic instruments to advanced technology highlights their enduring significance and relevance in today’s measurement-driven world.

By understanding their history, design features, and future trends, you can appreciate these items as more than just instruments—they are vital components in ensuring quality and accuracy in a diverse range of applications. Explore the world of these items and find the perfect instruments to enhance your measurement processes, reflecting both professionalism and commitment to excellence.

Whether for personal use or as part of a larger operation, a well-chosen item offers unparalleled accuracy and reliability, ensuring that your measurements are conducted with the utmost precision. Embrace the timeless importance of these products and make them a cornerstone of your measurement practices.