Precision and Accuracy: The Importance of Machinist Measuring Tools

Explore the essential world of machinist measuring tools, where precision meets craftsmanship in every measurement. Designed for accuracy in machining and manufacturing, these items are vital for ensuring that every component fits perfectly and functions optimally. Whether you are a seasoned or a hobbyist, having these products at your disposal is crucial for achieving high-quality results in your projects.

The Evolution of Machinist Measuring Tools: From Simple Beginnings to Advanced Precision

These options have a fascinating history, evolving from rudimentary instruments to sophisticated devices that enable highly accurate measurements. Initially, it relied on basic items like calipers and rulers, which were often handmade and varied significantly in quality and accuracy. The need for more precise measurements became apparent with the advent of the Industrial Revolution, which led to significant advancements in measurement technology.

By the late 19th and early 20th centuries, machinist measuring tools began to incorporate more advanced engineering principles. The introduction of standardized measurements and precision manufacturing techniques transformed the landscape of these pieces. The invention of these items like micrometers and dial indicators allowed to achieve unprecedented levels of accuracy, marking a pivotal shift in manufacturing processes.

In recent years, the evolution of these products have continued, driven by technological advancements and the demand for higher precision in manufacturing. Today’s product often feature digital displays, wireless connectivity, and advanced calibration systems. This modern technology ensures that can obtain accurate readings quickly and efficiently, ultimately improving the quality of their work.

The Cultural Significance of Machinist Measuring Tools

Machinist measuring tools hold cultural significance within the engineering and manufacturing communities, symbolizing the blend of skill, precision, and craftsmanship. In many cultures, the ability to create and measure with accuracy is highly respected, reflecting a deep appreciation for the art of machining and fabrication.

In Western cultures, these items are often associated with professionalism and technical expertise. They are seen as essential instruments for engineers alike, representing a commitment to quality and precision in every project. These pieces themselves have become symbols of mastery in the field, showcasing the skills and knowledge required to operate them effectively.

Furthermore, machinist measuring tools play a significant role in education and training. Many aspiring engineers learn to use these products as part of their technical education, emphasizing the importance of measurement accuracy in practical applications. This educational aspect ensures that future generations recognize and value the craftsmanship associated with these items.

The Design and Features of Machinist Measuring Tools

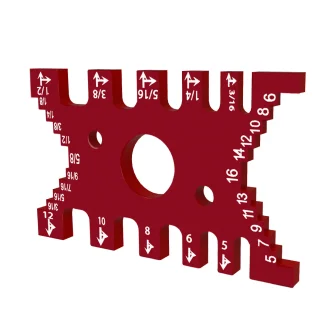

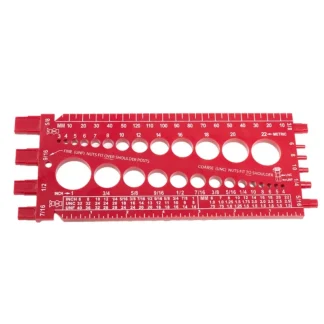

These products are renowned for their thoughtful design and innovative features. Common items include calipers, micrometers, height gauges, and laser devices. These products are designed to provide precise measurements with ease of use, ensuring that can obtain accurate readings quickly.

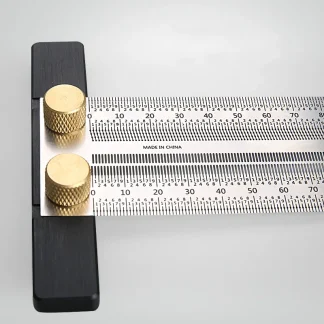

Classic measuring tools, such as vernier calipers and dial indicators, focus on simplicity and reliability. They are designed to withstand rigorous use while providing clear, accurate readings. The ergonomics of these items also play a vital role, as comfort and ease of handling are essential for achieving precise measurements during extended periods of use.

Modern products may include digital readouts, data storage capabilities, and advanced calibration systems. These innovations cater to contemporary needs, allowing for enhanced accuracy and efficiency. The integration of digital technology into traditional product reflects a growing trend towards automation and precision in manufacturing processes.

Innovations in Machinist Measuring Tool Design

Recent innovations in machinist measuring tool design have opened new avenues for precision and efficiency. Advances include the integration of digital technology, which allows for real-time data tracking and analysis. Digital calipers and micrometers now feature wireless connectivity, enabling seamless data transfer to computers and other devices for further analysis.

Customization has also become increasingly popular, allowing to choose these items that reflect their specific needs and preferences. This trend ensures can have these items that suit their individual style and work requirements, enhancing both productivity and comfort.

Sustainability has emerged as a key focus in the design of machinist measuring tools. Many manufacturers are exploring eco-friendly practices and materials, striving to reduce waste and environmental impact while maintaining high standards of accuracy and performance. This shift towards sustainable manufacturing reflects broader trends in the industry, providing conscientious options for modern.

The Future of Machinist Measuring Tools

The future of these products are poised to embrace ongoing innovation, customization, and sustainability. As technology continues to advance, designers are exploring new materials and features that enhance both functionality and aesthetic appeal. This ensures that these pieces remain relevant and effective in an ever-evolving industry.

Customization will remain a vital trend, allowing machinists to select tools that meet their unique requirements. This growing desire for personalized equipment reflects an appreciation for individual expression within the technical landscape, emphasizing the importance of these items that resonate with each style and approach.

As advancements in design and technology continue, these items will incorporate new features while maintaining their fundamental purpose. The focus on precision, ease of use, and personal expression will ensure that these products remain essential instruments, enhancing their ability to produce high-quality work consistently.

Choosing the Right Machinist Measuring Tool

Selecting the ideal machinist measuring tool involves considering factors such as the specific measurements needed, the level of precision required, and personal preferences. For projects requiring high precision, opt for advanced items like digital micrometers or laser devices that provide instant and accurate readings. If versatility is essential, calipers with interchangeable jaws can accommodate various tasks.

The design and functionality of these items should also align with your working style and environment. Whether you prefer traditional analog pieces for their reliability or modern digital devices for their efficiency, the right product can significantly enhance your work process and overall accuracy.

Confidence in your measuring tools will elevate your enjoyment and satisfaction in your machining projects, ensuring they serve as invaluable assets in your quest for precision. Embrace the importance of these items and discover how they can elevate your craftsmanship, providing the accuracy and reliability needed for exceptional results.

Conclusion: The Enduring Appeal of Machinist Measuring Tools

These options embody the perfect blend of precision and craftsmanship, offering essential solutions for accurate measurements in machining and manufacturing. Their evolution from simple instruments to advanced items highlights their enduring significance and relevance in the technical world.

By understanding their history, design features, and future trends, you can appreciate machinist measuring tools as more than just equipment—they are symbols of skill, accuracy, and dedication to the craft. Explore the world of these products and find the perfect additions to your toolkit, reflecting both innovation and expertise.

Whether for professional use or personal projects, a well-designed product provides unmatched accuracy and functionality, ensuring that every measurement is precise and reliable. Embrace the enduring appeal of these products and make them a vital part of your machining journey.

+ 5

+ 5